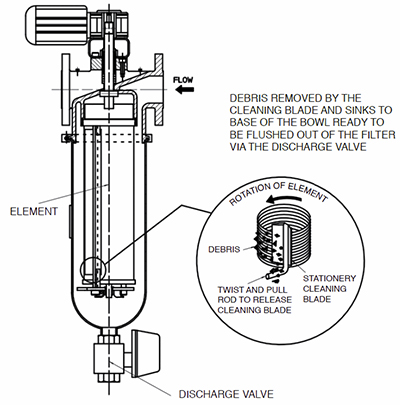

- Element cleaning without stopping or disrupting the fluid flow.

- Element cleaning without significant fluid loss.

- Fully enclosed system.

- No operator contact with the fluid, ideal for hazardous or sensitive applications.

- No externally introduced contamination issues, increases confidence in the quality of the filtered product.

- Clean operating area and easy environmental contamination control.

- Suitable for virtually all fluids of all viscosity levels.

Factors to be Taken Account of when Selecting a Strainer:

- Fluid type

- Flow rate

- Viscosity

- Temperature – operating and design

- Pressure – operating and design

- Degree of filtration required

- Connection type i.e. flanged PN16, ASA150, screwed BSP, NPT

- Any special requirements i.e. heating jacket, magnets, mounting brackets, dp indicator/switch etc.

- Paint and coatings industry

Used as a fully automated quality control measure to ensure paint, ink , varnish etc is free of unwanted particulates in the process and filling lines. Used to replace paint bag filters, open sieves and other more labour intensive filtration methods. - Chemical industry

Used for filtering process chemical liquids on a automated basis to protect pipeline equipment, as a quality control measure and replacing more manual methods of filtration generally. - Paper industry

Frequently used for process water for example in the protection of spray nozzles on paper making machinery and also used on raw water intake and cooling water. - Power

Used on industrial water for cooling and the filtration of sealing water to increase the service life of turbine shaft seals. - Water industry

Used throughout the industry for straining of raw water usually before other finer filtration methods and on waste water treatment plant etc. - Food

Used on suitable applications for example in the chocolate industry as a quality control measure and in the meat industry for process water filtration.

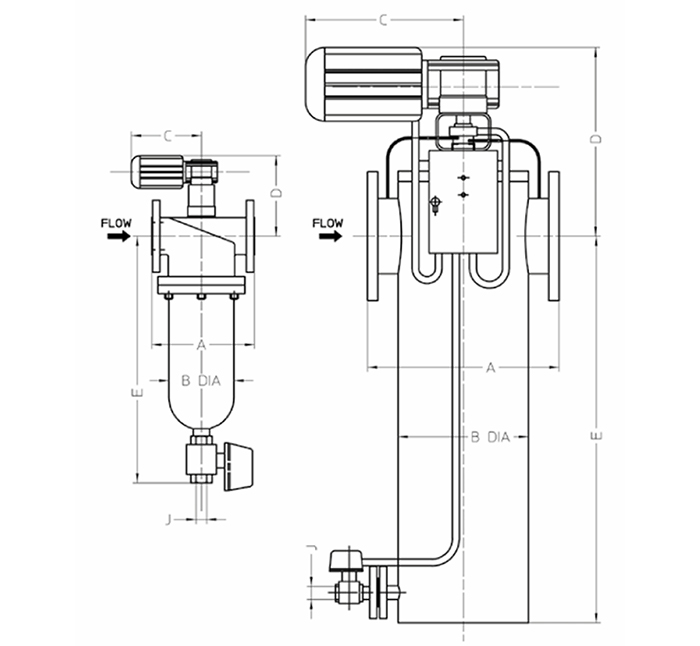

| Threaded Units (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | A | B | C | D | E | F | G | H | J |

| 40 | 220 | 157 | 260 | 245 | 555 | 150 | 185 | 250 | 3/4" |

| 50 | 220 | 157 | 260 | 245 | 555 | 150 | 185 | 250 | 3/4" |

| 65 | 220 | 157 | 260 | 245 | 555 | 150 | 185 | 250 | 3/4" |

| Flanged Units (mm) | ||||||

|---|---|---|---|---|---|---|

| Size | A | B | C | D | E | J |

| 50 | 325 | 157 | 260 | 245 | 555 | 3/4" |

| 80 | 360 | 190 | 260 | 255 | 645 | 1-1/2" |

| 100 | 550 | 280 | 345 | 380 | 880 | 1-1/2" |

| 150 | 550 | 406 | 345 | 560 | 1170 | 1-1/2" |

| 200 | 870 | 700 | 345 | 560 | 1170 | 1-1/2" |

| 250 | 1000 | 800 | 345 | 560 | 1170 | 1-1/2" |

| 300 | 1100 | 865 | 345 | 560 | 1170 | 1-1/2" |

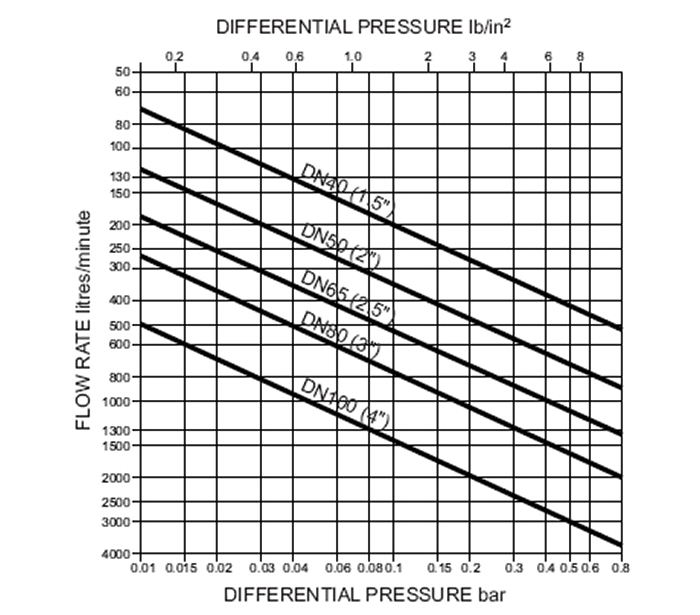

Sizing and Differential Pressure Calculations

Please provide the following and we will advise:

- Flow rate

- Liquid

- Viscosity

- Removal Size of Screen

| Parts and Accessories | ||

|---|---|---|

| Code | Description | Link |

| XSK50SCV | Service Kit - Viton (DN40,50,65) | More Information |

| XSK50SCE | Service Kit - EPDM (DN40,50,65) | More Information |

| XSK80SCV | Service Kit - Viton (DN80) | More Information |

| XSK80SCE | Service Kit - EPDM (DN80) | More Information |

| XSK100SCV | Service Kit - Viton (DN100) | More Information |

| XSK100SCE | Service Kit - EPDM (DN100) | More Information |

| 20020 | Element Bearing | |

| 20014 | Scraping Blade Set | More Information |

| 2000 | Element |

More Information |

| BKT-AS-AC-01 | Ratchet Handle & Clip | More Information |

XCLPS-HP Flanged - (50 Bar)

Oxford XCLPS-HP blade style self clean filters for pressures up to 50bar are used for the filtration of virtually all fluids from water to very high viscosity fluids where the filter is cleaned without the operator accessing the unit or even on a completely automatic basis with no operator involvement in the cleaning operation.

Oxford Filtration's innovative self-clean filter technology offers you improved output, greater efficiency and consistent quality in a cost-effective and reliable package.

Optional Auto Package - Mode of Operation

As the filter collects debris, the pressure drop across the filter increases. This increase will operate the Differential Pressure (DP) switch (which is factory set at 0.35bar / 5 lb/in²). The operation of this switch causes the cleaning motor to run for a fixed time, thus removing the debris from the element. After a number of motor operations, the discharge valve will open (and then close) to discharge the debris from the filter.

The user also has the option to have the cleaning motor and/or discharge valve operate at fixed time intervals.

XCLPS-HP Self Clean Filter - Flanged

- Brand: Oxford

- Product Code: XCLPS-HP Self Clean Filter - Flanged

- Availability: Price & Delivery on Quote

-

$0.00

- Ex Tax: $0.00